About LifePO4 Powers

Factory-Grade LiFePO4 Production for Global Projects

Awesome Services from LifePO4 Powers

We focus on four solution pillars to match real project needs—from portable off-grid connectivity to large-scale energy storage. Each product is engineered around LiFePO4 safety, long cycle life, and smart BMS protection.

- Starlink Mini Battery (180 Wh): 7–10.5 h runtime, 5000+ cycles, IP65, –30–50 °C, Samsung cells

- Custom LiFePO4 Packs (12–51.2 V): golf cart/RV/marine/home; series/parallel; waterproof/vibration-resistant options

- C&I Energy Storage & UPS: modular racks, three-phase support, EMS-ready, <10 ms UPS transfer with remote monitoring

Mission-Driven Leadership

Vision: Off-grid without losing power—trusted LiFePO4 energy tailored to each scenario.

Our team spans structural, electrical, cell, assembly, and testing engineering. We move quickly from specification to certified product, providing drawings, validation plans, and documentation to keep your timelines on track.

Vision — LifePO4 Powers

We aim to become a trusted global LiFePO4 brand by combining product safety, long service life, and customization with responsive engineering support.

- Safety first: LiFePO4 chemistry + premium Samsung cells + multi-level BMS protection

- Longevity & reliability: typically 6000–10,000 cycles depending on application

- Customization & scale: voltage/capacity/enclosure/interface tailored for OEM/ODM projects

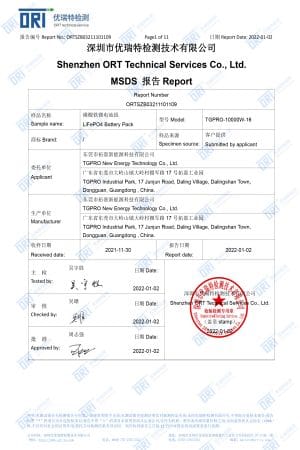

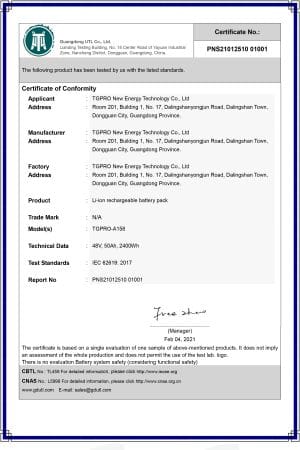

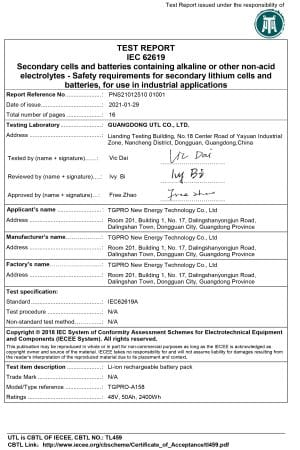

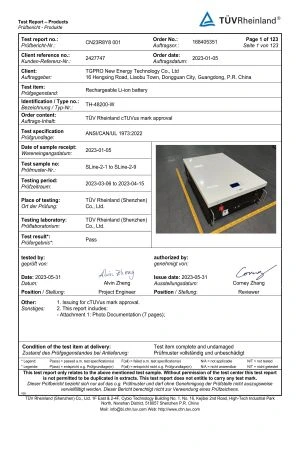

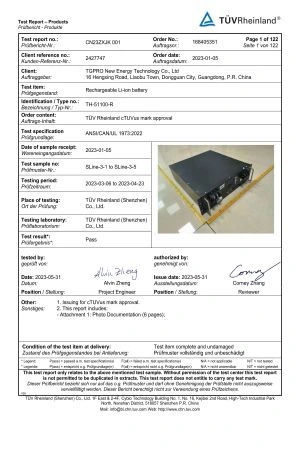

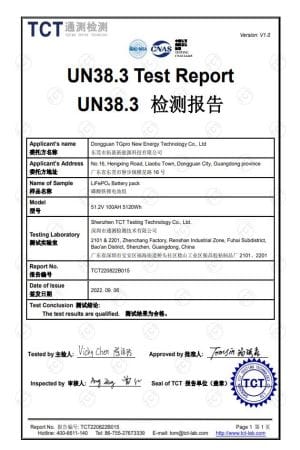

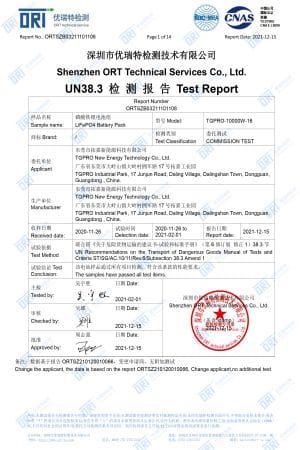

The Advantage Is in Our Quality

We pair automated manufacturing with 100% functional testing and traceable QA. Every shipment includes relevant reports to support certifications and import compliance.

- ISO 9001 quality management across design, assembly, and testing

- UN38.3/CE/RoHS/FCC by model; MSDS and transport files prepared for export

- Global Product Liability Insurance for customer assurance

- In-house capabilities: cell sorting (capacity/IR), precision welding, aging/burn-in, high/low-temperature and vibration tests

YEAR EXPERIENCE

PROJECTS DELIVERED

CUSTOMERS SERVED

Certification

Production Process

R&D

Our R&D team can help design and analyze the battery or energy storage system you need.

Cell Matching

As part of our quality control process, each cell is measured and sorted into categories based on capacity levels.

Terminal Connection

Tab connections, welding, short circuit protection, laser marking.

Assembly

The assembly process is key to ensuring optimal battery performance.

BMS Testing

Battery Management System with Bluetooth, communication, or remote control support.

Aging & Testing

Our burn-in testing department has extensive experience in verifying the integrity and quality of welded or sealed housing assemblies.

Partners Who Trust LifePO4 Powers